The Fundamentals: How Filter-Based Imaging Colorimeters Work

Filter-based imaging colorimeters measure color and brightness precisely by combining high-resolution imaging with specialized optical filters aligned to human vision standards.

Core Components Breakdown

| Component | Function |

|---|---|

| High-resolution sensors | Capture millions of data points over a display for detailed spatial color analysis |

| Tristimulus optical filters | Mimic the CIE 1931 color-matching functions (XYZ filters) to align measurements with human vision |

| Optics and calibration | Motorized focus ensures sharp imaging; Smart Calibration™ systems maintain accuracy over time |

Measurement Principles

The device captures light through the sensor and filters, converting it into tristimulus values that quantify:

- Luminance: Brightness levels of each pixel or region

- Chromaticity: Color coordinates that describe hue and saturation

This process creates precise 2D color maps corresponding to what the human eye would perceive.

Technical Edge

- Correlates measurements closely with human visual perception through CIE color-matching

- Provides rapid, full-field 2D imaging for real-time uniformity and color distribution analysis

In short, filter-based imaging colorimeters offer a fast and accurate way to assess display quality by quantifying color and brightness just like our eyes do—but with the precision and repeatability required for modern manufacturing and R&D.

Key Advantages: Why Choose Filter-Based Imaging Colorimeters

Filter-based imaging colorimeters offer clear benefits over traditional methods and spectroradiometers—especially for U.S. industries aiming for fast, accurate color and luminance testing. Here\’s a straightforward look:

| Advantage | What It Means for You | Notes |

|---|---|---|

| Speed & Scalability | Measures entire displays in one shot | Cuts test times by up to 90% |

| Cost-Efficiency | Lower upfront cost than spectroradiometers | Maintains sub-1% color accuracy |

| Precision & Repeatability | Detects uniformity issues with high consistency | Ideal for spotting mura defects |

| Limitations & Solutions | Potential metamerism (color mismatch) risks | Hybrid setups combining filters + spectral can help |

| Proven ROI | Real data shows fewer defects in HUD displays | Award-winning tech trusted by auto & aerospace sectors |

Filter-based systems deliver fast, reliable results without the hefty price tag of full spectral devices. Plus, their precision in uniformity testing makes them a top pick for quality control on factory floors across the U.S. When metamerism is a concern, pairing filters with spectral tools balances performance and accuracy.

If your goal is rapid, scalable testing with consistent output and lower cost, filter-based colorimeters are a smart choice.

Real-World Applications: From R&D Labs to Factory Floors

Filter-based imaging colorimeters are proving their worth across many industries, from research labs to busy production lines.

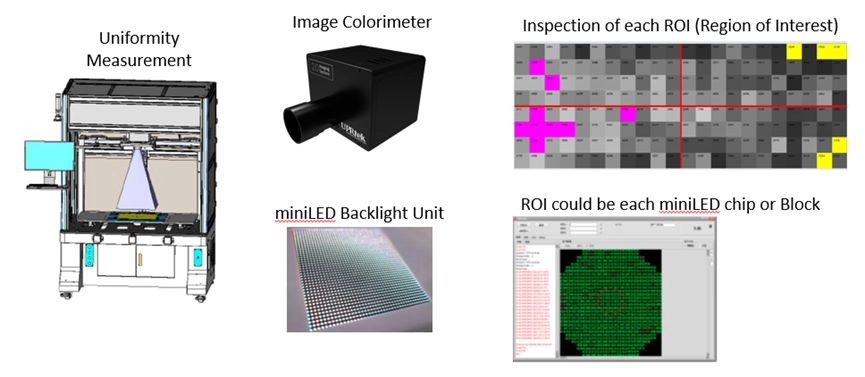

Display and Backlight Inspection

These systems excel at checking displays, including OLED uniformity. For example, in OLED panels, they quickly spot mura defects—those annoying uneven spots—ensuring every screen looks perfect before shipping.

Automotive and Aerospace Lighting

In automotive and aerospace, these colorimeters inspect HUDs (heads-up displays) and instrument clusters. They verify accurate luminance and color consistency, critical for safety and driver comfort.

Backlit Components and Medical Imaging QC

Backlit components, like LED panels and medical imaging devices, benefit from precise luminance and chromaticity checks, helping avoid failures and keep image quality sharp.

Emerging Uses: AR/VR and Flexible Displays

As AR/VR gadgets and flexible screens grow, so does the need to catch defects early. Filter-based imaging colorimeters spot color shifts and brightness inconsistencies, making them perfect for this emerging market.

Integration and Automation

These colorimeters easily integrate into automated vision systems, speeding up production quality checks. Plus, with Jingce API compatibility, data flows seamlessly into existing software for real-time defect flagging and analysis.

Whether you’re improving product quality or speeding up production, filter-based imaging colorimeters are designed to fit modern manufacturing needs in the U.S. marketplace.

Implementation Best Practices: Setting Up for Success

Getting the most out of your filter-based imaging colorimeter starts with the right setup. Here’s what to focus on:

Choosing the Right System

- Resolution: Higher resolution sensors give you more detailed color and luminance data, crucial for spotting tiny defects like mura.

- Field of View (FOV): Match the FOV to your display or light source size. Too wide, and you lose detail; too narrow, you miss edges or patterns.

- Filter Bandwidth: Narrower bandwidth filters improve color accuracy but may increase cost. Balance based on your precision needs.

Calibration Essentials

- Use flat-field correction to eliminate sensor shading and lighting inconsistencies. This keeps color measurements uniform across the entire sensor.

- Recalibrate regularly to maintain accuracy, especially when environmental lighting or equipment changes.

- Keep an eye on frequency-related noise during measurements—adjust acquisition settings as needed to reduce interference.

Avoiding Common Pitfalls

- Oblique angles: Position your system perpendicular to the display to prevent color shifts caused by angle-dependent filter responses.

- Environmental noise: Control ambient light and reflections to avoid skewed data. Use shielding or dark rooms if possible.

- Multi-lens setups: Ensure proper alignment and calibration for each lens to avoid mismatched data and stitching errors.

Leveraging Software Features

- Use software tools for POI (Points of Interest) and ROI (Regions of Interest) mapping to focus on critical areas.

- Enable defect flagging to automatically spot and report uniformity issues or color errors.

- Export data for Statistical Process Control (SPC) to track trends and improve production quality over time.

Meeting Safety and Compliance

- Follow ISO 3664 standards for viewing conditions and color matching. This helps maintain consistency and reliability, especially in industries where color accuracy matters deeply, like automotive or medical displays.

By following these best practices, you’ll ensure your filter-based imaging colorimeter delivers accurate, reliable results every time—helping you keep quality high and defects low on the production floor.

Jingce Solutions: Elevating Your Measurement Capabilities

At Jingce, we lead the way in precision imaging and spectroscopy, providing reliable filter-based imaging colorimeters that meet the demands of today’s quality control challenges. Our expertise ensures you get accurate, repeatable results that help optimize your production line QC and color uniformity testing.

JCI Series and Hybrid Spectral Options

Our JCI series stands out with high-resolution color sensors paired with advanced tristimulus XYZ filters aligned to CIE color-matching functions. These units deliver fast, precise luminance measurement and chromaticity analysis in one shot. For customers needing even deeper insight, we offer hybrid filter-spectral instruments that combine the speed of imaging photometers with the accuracy of spectroradiometer calibration.

Customization and Support

We know every project is different. That’s why Jingce provides customizable lenses to suit your field of view (FOV) needs and filter bandwidths based on your specific application. Our global support network, including dedicated teams across the US, means you get expert help at every step. Plus, our US client case studies show proven improvements in mura defect detection and automotive display inspection workflows.

Get Started Today

Ready to improve your colorimetric testing accuracy without breaking the budget? Download our free calibration guides and schedule a demo to see how Jingce’s filter-based imaging colorimeters can streamline your process and reduce defects. We’re here to help you get the best ROI on your quality control efforts.

Future Trends: The Evolving Role of Filter-Based Imaging in Smart Manufacturing

Filter-based imaging colorimeters are stepping into a new era, driven by smart manufacturing demands here in the U.S. Here’s what’s shaping their future:

-

AI and Machine Learning: These tools are making a big impact by analyzing colorimetric data faster and smarter. They help predict defects before they become costly problems, improving quality control on production lines.

-

Better Filters: Advances are bringing narrower bandwidths and adaptive filters that adjust in real-time. This means even more accurate color and luminance measurements, improving uniformity detection for everything from OLEDs to LED backlights.

-

Sustainability Gains: Faster, precise measurements reduce waste by cutting down errors early in manufacturing. That’s a win for efficiency and the environment, helping companies meet green goals while saving money.

-

Growing Market Demand: With electric vehicle displays and 8K screens gaining ground worldwide — especially strong in the U.S. market — the need for reliable, rapid color measurement is only increasing. Filter-based imaging systems are perfectly positioned to support this growth.

As smart factories become the norm, filter-based imaging colorimeters will be central to keeping quality high, costs low, and sustainability on track.